Volume Handling

Introduction

The determination of unit operation volumes is essential for equipment planning and operating cost estimates. Operation volumes can be estimated from the utilized unit operation materials and their volume role; alternatively (and more accurately), they can be scaled up from observed small scale volumes. Both volume determination methods are outlined below.

Calculated Unit Operation Volumes

While the sum of all utilized reagents and solvents of a unit operation provides a first approximation of the involved volume, material volume properties allow for a more accurate assessment:

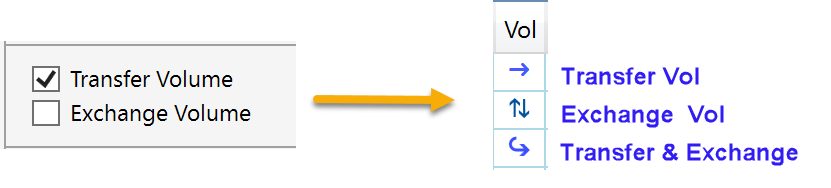

Transfer Volume:

This is a material volume which is transferred from one unit operation to another. Materials marked as transfer volumes are duplicated into the following unit operation, where they contribute to its volume, but not to its costs. If desired, they can be further transferred downstream to create a volume transfer chain. Check the Transfer Volume checkbox to specify a material as transfer volume.

![]() Click the Transfer All button, located in the header of the material table, to assign all unit operation materials as transfer volumes. Or click the button to its right to clear all transfer volumes.

Click the Transfer All button, located in the header of the material table, to assign all unit operation materials as transfer volumes. Or click the button to its right to clear all transfer volumes.

![]() In case of e.g. a distillation or evaporation, often only a variable part of the initial volume is transferred to the next unit operation. Enter the desired percentage in the Transfer Vol panel (Source Data section) to specify such a partial volume transfer. Please note that this panel only appears for non-materials consuming unit operations containing materials transferred from the previous unit operation.

In case of e.g. a distillation or evaporation, often only a variable part of the initial volume is transferred to the next unit operation. Enter the desired percentage in the Transfer Vol panel (Source Data section) to specify such a partial volume transfer. Please note that this panel only appears for non-materials consuming unit operations containing materials transferred from the previous unit operation.

Exchange Volume

Typically exchange volumes are applied for extractions, where solvents are repeatedly added and removed. Simply adding up solvent volumes here would provide a much higher than actually required volume.

Check the Exchange Volume checkbox for each material which is added and removed during the same unit operation. Only the material with the highest exchange volume contributes to the effective maximum. The specification of only one exchange volume per unit operation has no specific effect.

Transfer & Exchange Volume

Both of the above volume attributes can be concurrently assigned to a material, resulting in material which is first exchanged and subsequently transferred into the next unit operation.

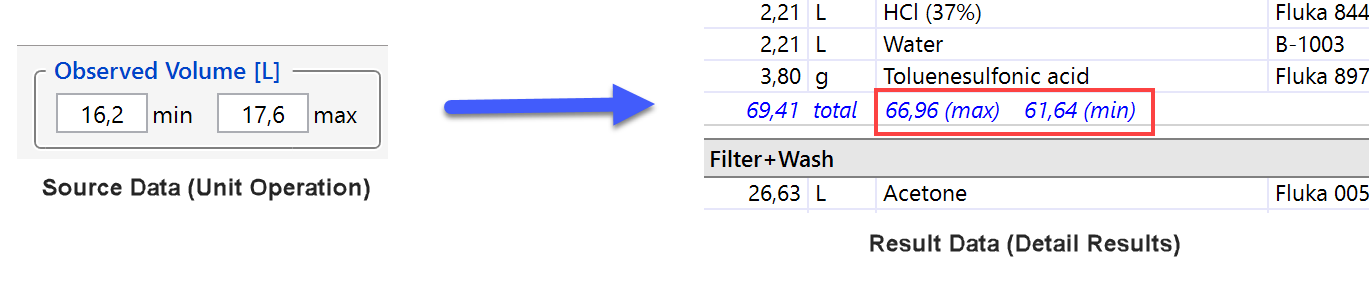

Observed Unit Operation Volumes

The most accurate method for the determination of unit operation volumes is the observation of the corresponding small scale volumes and subsequent, application performed scaling to the desired campaign size. Maximum volumes determine the minimum equipment size, while minimum observed volumes support the assessment of stirrability in low volume situations.

ChemProject supports observed volumes as shown above. Whenever observed unit operation volumes are specified (left), they are scaled to the current campaign size, (right), along with the estimated volumes to their left.